Orthopaedic Implants And Instruments List

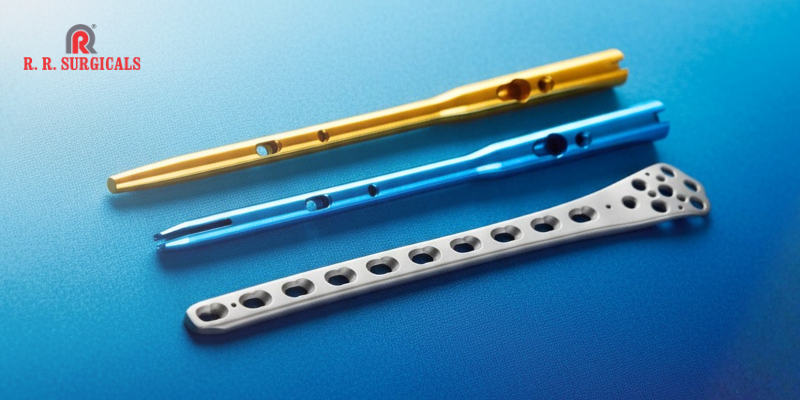

1. Intramedullary Nails

The demand for quality intramedullary nails is rising due to a focus on faster recovery, increasing fractures, advancements in surgical techniques and more. Since they are inserted directly into the medullary cavity, they should be able to provide internal support and help in healing. A trauma implants manufacturer in India with a vast product portfolio can help get nails according to the requirements.

2. Locking And Non-Locking Screws

Fragile bones or multi-fragmented fractures need locking screws, unlike non-locking screws that are ideal for simple fractures. Angular and rotational stability, resistance to bending and more are the factors to be considered while looking for these orthopaedic implants in India.

3. Locking And Non-Locking Plates

Locking plates act as the fixed-angle construct, while the non-locking plates provide compression for a simple fracture. However, they should be able to maintain structural integrity under mechanical stress. Also, such bone implants in India should be precise and have surface smoothness.

4. Extractors And Fixators

While removing broken implants safely without damaging bone or soft tissue and stabilising fractures, the extractors and fixators are used. But quality should be ensured while getting these orthopaedic implants and instruments in India because they have to withstand mechanical stress during extraction or fixation.

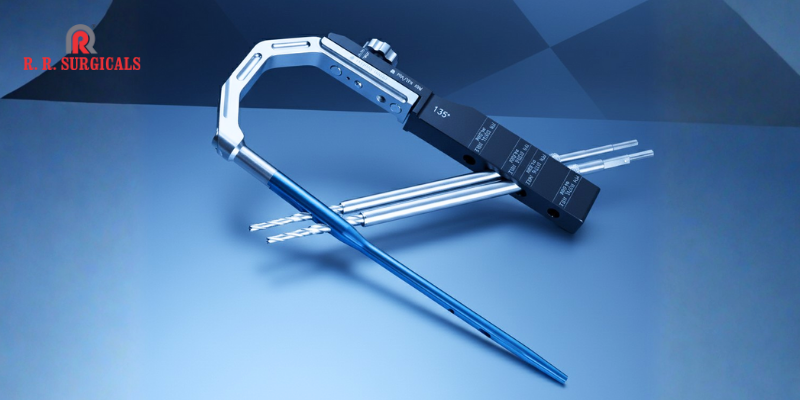

5. Instruments

Finding quality orthopaedic instruments in India helps reduce inaccurate placement, longer surgery time and infection risks as they are used for drilling, fixation and reaming of implants. Additionally, their material matters as it affects their ease of getting sterilised and the ability to be minimally invasive.

Manufacturer Of Quality Orthopaedic Implants And Instruments In India

1. A Diverse Product Portfolio

R. R. Surgicals offers all the above-mentioned orthopaedic implants and instruments in India and abroad. They are available in multiple sizes and lengths and can be modified according to the diverse surgical needs.

2. Medical-Grade Materials

R. R. Surgicals manufactures orthopaedic implants and instruments in India using medical-grade materials (Titanium, SS 316L and SS 316LVM). Here, raw materials go through strict internal and external inspection at the very first stage, and the further product process is maintained according to the ISO13485:2016 and CDSCO standards.

3. Advanced Technology

Programmable Machines and New Generation CNC are used for manufacturing accurate bone implants in India at its 40,000 sq. ft. advanced unit. Additionally, the employees are trained to operate these advanced machines while maintaining the product quality.

4. In-Process Inspection

Precise gauges and calibrated instruments are used at R. R. Surgicals to ensure accuracy at every stage. It is also associated with the final inspection before packaging.

5. Cleanroom Packaging

Final packaging and labelling are done in the cleanroom while implementing the right measures to avoid contamination. Similarly, the products are stored with a focus on quality standards to prevent unnecessary handling.

6. Product Export

R. R. Surgicals manufactures these orthopaedic implants and instruments in India and supplies them to most of the major cities. It also exports them to Africa, the Middle East and other South Asian countries with a global footprint.

Found The Ortho Implants And Instruments You Were Looking For?