35+ Years Of Excellence In Orthopaedic Products

Known for the top quality, globally

35+ Years Of Excellence In Orthopaedic Products

The Story Of Our Growth

Founded in 1990, R. R. Surgicals is a certified CDSCO and ISO 13485:2016 company, well-recognised in our field for manufacturing orthopaedic implants and instruments with a strong focus on trauma solutions. We have proudly reached new heights under the leadership of our Director, Mr. Rasik Bhalodia. Originally established in Mumbai, we made the strategic decision in 2021 to relocate to a larger, more advanced facility in Valsad, Gujarat.

From The Director's Desk

Mr. Rasik Bhalodia, Director

Our Core Focus

Shaping the future of orthopaedics

Vision

- Improve surgical outcomes and patient recovery

- Innovate healthcare and medical procedures

- Lead the industry globally

- Encourage research and advanced techniques

Mission

- Empower professionals with precise products

- Focus on improvement consistently

- Continue providing quality products

- Promote employee training and education

Our Values

Quality

Following strict quality standards in manufacturing.

Responsibility

Striving to improve people’s quality of life.

Excellence

Meeting high standards of efficacy and safety.

Improvement

Improving to meet challenges in the medical field.

Milestones Of Success

The Foundation

- Started the company in Vasai (Mumbai) at a rented place

- Began the journey by manufacturing CORTICAL SCREWS

Expansion And Innovation

Developed INTER LOCKING FLARRING NAIL IN SINGLE PIECE

Achieved a Milestone

Became India’s first company to launch FLARRING NAIL WITH CRIMPING

Set New Standards

- Developed DHS PLATE ROUND HOLE

- Developed DHS PLATE WITH DCP HOLE

Increased Production Capacity

- The company owned its first unit

- Began manufacturing products for the spine

Stepped Towards Precision

- Purchased the first JAPANESE VMC MACHINE

Facility Expansion

- Expanded by purchasing new space beside the company, combining units

Global Outreach

- Visited Singapore

- Purchased VMC (MAKINO), SLIDING AUTO HEAD (CITIZEN) and GUNDRILL MACHINE

FDA Approval

- Became one of the few companies to get issued an FDA License

Strategic Relocation

- Shifted our company from Vasai (Mumbai) to Valsad (Gujarat)

Continued Growth

- Got issued with the CDSCO LICENSE in our new unit

- Added new JAPANESE VMC, CNC and GUNDRILL MACHINES

- Added new products in Intramedullary Nails, Locking and Non-Locking Plates, Screws, Extractors & Fixators and Instruments

- Upgraded our product portfolio

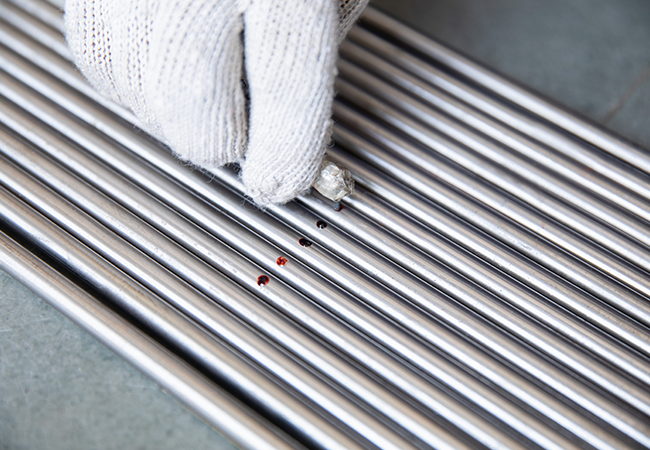

Our 14-Step Manufacturing Process

1. Raw Material Area

2. In-House & Outsourced Material Test

3. Hardness Testing

4. Gun Drilling

5. 5-Axis VMC Machine

6. CNC Machine

7. In-Process Inspection

8. Buffing Machine (Auto Polish)

9. Sand Blasting Machine

10. Ultra Cleaning

11. Laser Marking

12. AHU - Cleanroom

13. Finished Goods

14. Dispatch

Our Global Reach

Need Orthopaedic Trauma Products For Your Surgical Accuracy?